Capabilities

Machines & Equipment

Our expansive 26,000m² factory is equipped with a range of specialist plastic manufacturing equipment situated on a 66,000m² site.

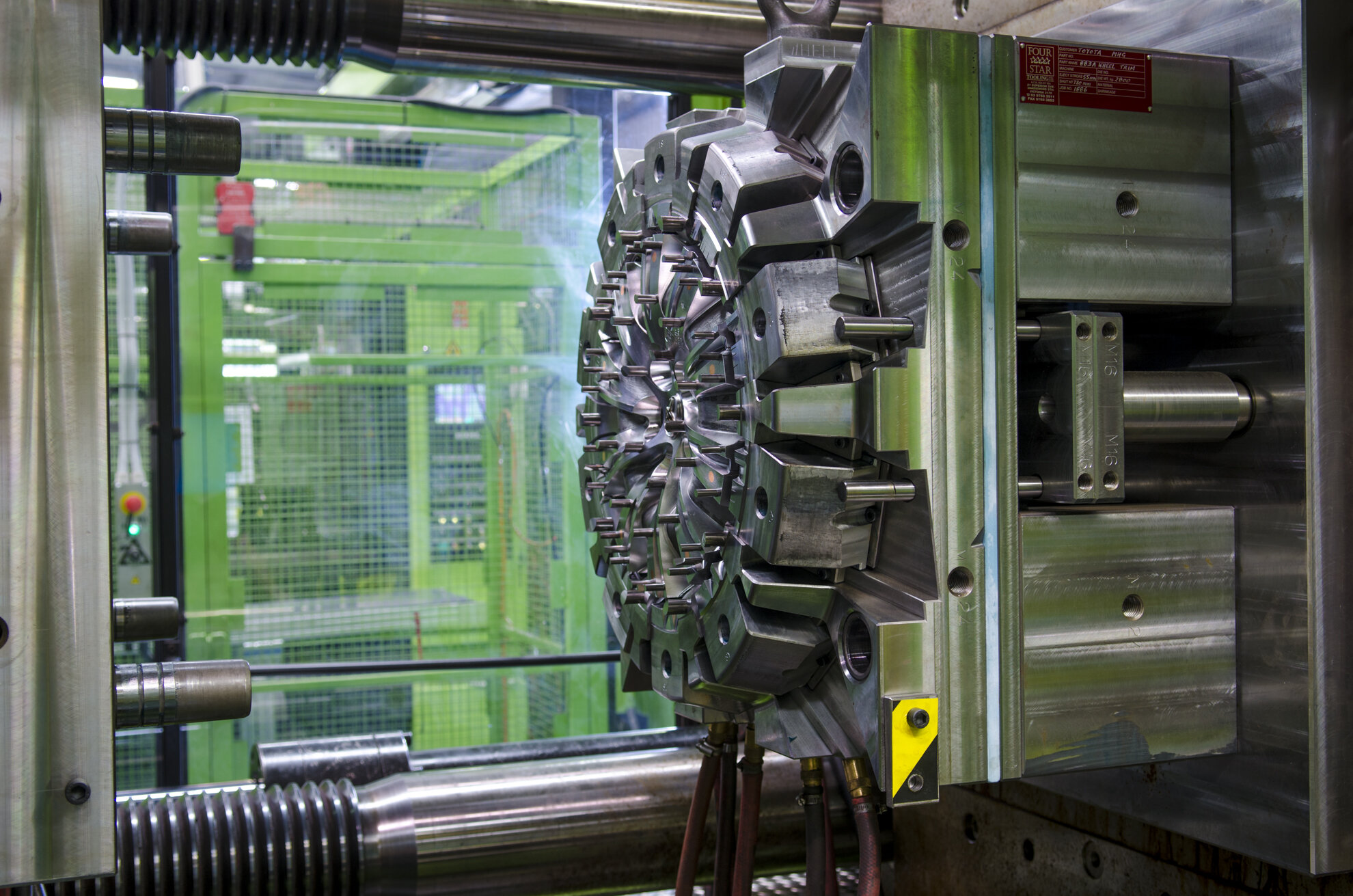

27 Injection moulding machines from 100T to 3,000T clamping force

Three blow moulders

Three plastic extruders

Fully equipped tool room

Automation and robotic process capabilities

Product evaluation capabilities including 3D scanning, CMM and large object measurement

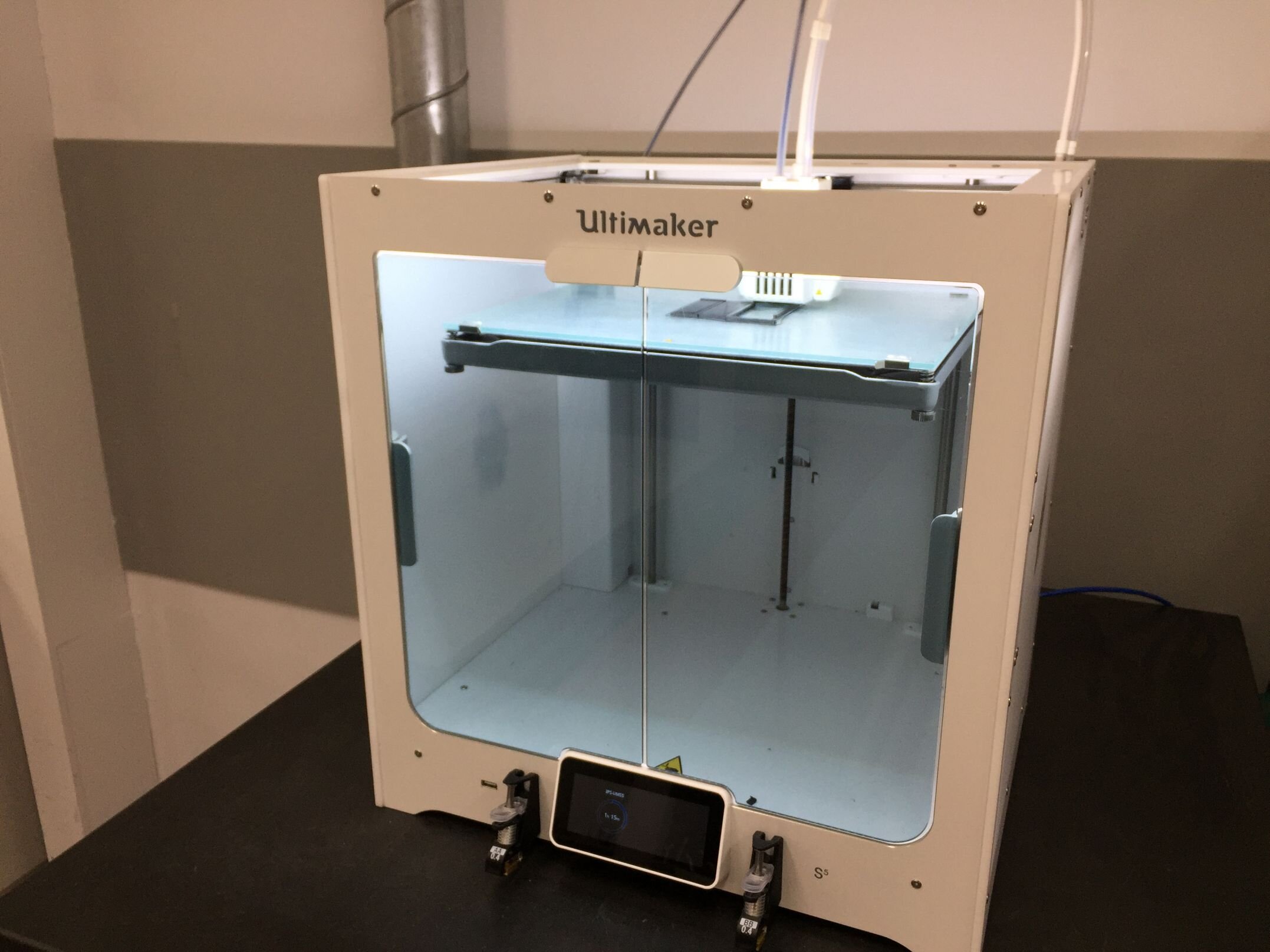

Product development capabilities including 3D printing, laser cutting and sewing

Services

Our HQ combines manufacturing capabilities and engineering expertise under one roof. We have the capability to manage the total product life cycle from development to manufacturing and end of life. When it comes to making things, we can help at any stage. Our mission is to make your ideas a reality.

Concept development and design

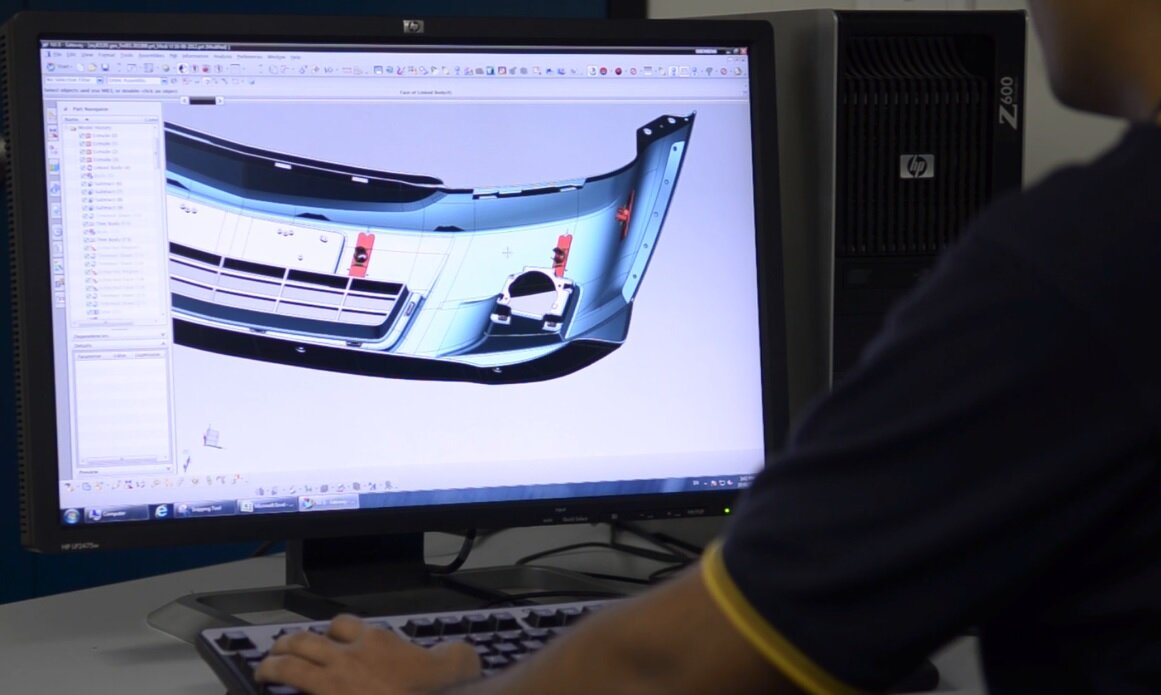

2D & 3D Computer Aided Design (CAD) and Computer Aided Engineering (CAE)

Accurate and functional physical prototyping

Process optimisation with fabrication of jigs and fixtures

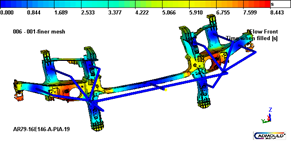

Finite Element Analysis (FEA), product validation and testing

On-site manufacturing

CMM aided design and dimension control

Design For Manufacturing (DFM) and Design For Assembly (DFA) evaluation

Test laboratory with temperature and humidity cycling chamber

External manufacturing and procurement through our global network of group companies